Support OpenDurham.org

Preserve Durham's History with a Donation to Open Durham Today!

OpenDurham.org is dedicated to preserving and sharing the rich history of our community. Run by our parent nonprofit, Preservation Durham, the site requires routine maintenance and upgrades. We do not ask for support often (and you can check the box to "hide this message" in the future), but today, we're asking you to chip in with a donation toward annual maintenance of the site. Your support allows us to maintain this valuable resource, expand our archives, and keep the history of Durham accessible to everyone.

Every contribution, big or small, makes a difference and makes you a member of Preservation Durham. Help us keep Durham's history alive for future generations.

Comments

Submitted by Larry (not verified) on Mon, 2/10/2014 - 2:24pm

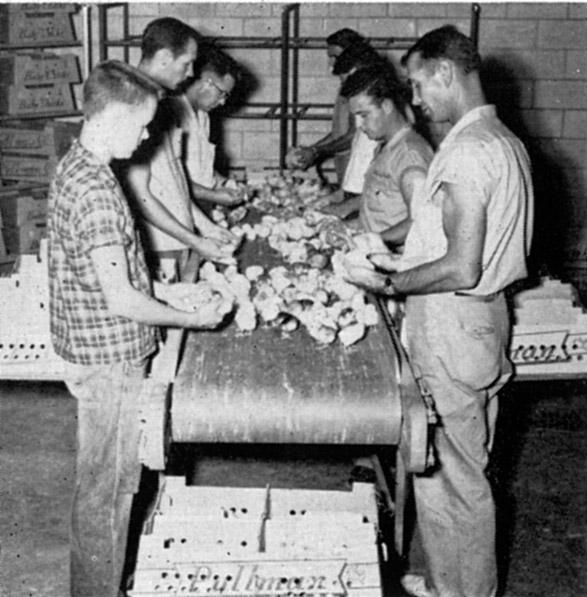

My dad worked here and he helped me get a job here back in the late 70's. How times change. If it had been a beer brewing factory back then, I may have still been employed there. :)

Add new comment

Log in or register to post comments.