The Durham Hosiery Company had its beginnings in 1894, when it was organized by George Graham, and began operations in a building on Church Street, and subsequently, Morris Street. Later that same year, Julian S. Carr (who had achieved wealth and fame as President and partner in first Blackwell's and then the Bull Durham Tobacco Company) and John W. Smith organized the Golden Belt Hosiery Company and located the new company at Five Points, at "the southward intersection of Main and Chapel Hill Sts. The founding of the Durham Hosiery Company was consistent with a national shift of textile manufacturing from the northeastern to the southern United States. While the southern mills were generally built with northern capital, lower costs of production caused the southern textile industry to experience explosive growth

Among other factors, climate, taxes, cheaper land, proximity to cotton fields, lower costs of construction, lower costs of labor, and lower prevalence of unions all contributed towards this shift.

Finding that neither could compete successfully with northern textile mills, the Durham Hosiery Mills Corporation merged with the Golden Belt Hosiery Company in 1898. Capitalized at $46,000, the company was taken over by Julian Carr.

The early Durham Hosiery Mill was located on the third, fourth, and fifth floors of a building of Morris Street in central Durham above a tobacco concern, W. W. M. Fallon and Company. Carr hired E. P. Sheridan, a manager experienced in the New England hosiery business, to run his mill. At about the same time the start of the Spanish- American War brought orders pouring in for cotton hosiery, protected against foreign competition by the 1897 Dingley Tariff Act.

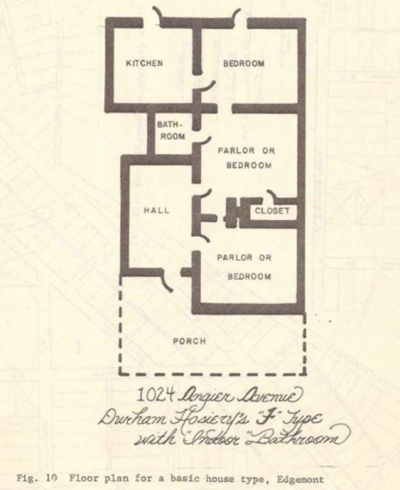

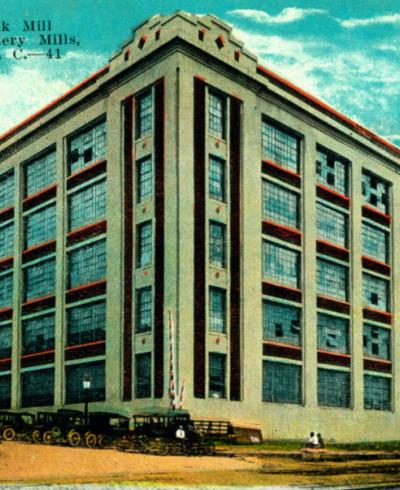

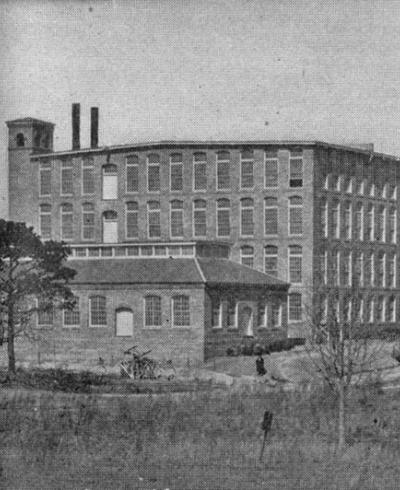

The Durham Hosiery Mills Corporation prospered. By 1901 it moved its machinery into its own building on Angier Avenue in a sparsely settled area of East Durham, which Carr termed “Edgemont.” The original mill building was completed in April, 1902.

The original operations included areas for knitting, carding, and spinning, with fleecing, picking and storage located in separated areas of the mill. Multiple annexes and additional buildings expanded the operations from 1906-1912.

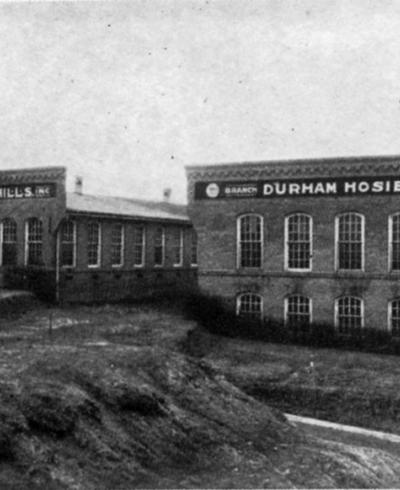

Julian Carr, Sr. had retired from Durham Hosiery Mills in 1911, and operation of the business was taken over by Julian S. Carr, Jr., who became the company president. Under the younger Carr, in 1903 the company opened its second mill in an old furniture factory several blocks southwest of the main mill (Durham Hosiery Mill Number 2). It was the first mill in the United States which employed a solely African-American work force.

Under the younger Carr's direction, the Durham Hosiery Mills instituted form of industrial democracy which survived from late in 1919 until early in 1921. According to the "Employee Representation Plan of the Durham Hosiery Mills,” a House of Representatives and a Senate were established at each mill (except the one with African-American workers) to represent the employees, with a Cabinet composed of executive and supervisory personnel meeting at regular intervals to respond to the legislation proposed by those two bodies. Decisions of the Cabinet could be overridden by a two-thirds vote of the entire membership of both houses as long as the bills would not radically affect the finances, the working house, or the progressive policy of the Durham Hosiery Mills Corp.

"It was a laboratory experiment to find the solution for the general problem of capital and labor,” explained Julian Carr, Sr.. The 'experiment' worked well enough--the workers were satisfied and no union was established--but when the company had to cut back work hours and then lay off workers due to the broader slump in the cotton hosiery industry, the representatives as well as others were released and the plan fell apart.

The slump which caused the collapse of the cotton hosiery industry began shortly after World War I as American women turned increasingly to silk hosiery, and the wartime demand ceased.. Overproduction and the effect of pricing pressure first manifested in the northern mills; employment dropped at the Fall River, Massachusetts mills by 10,000 workers in 1923-1924, with a decrease in product value by $40 million. Southern mills, which continued to expand during this period, were not spared for very long. By 1925, southern capacity exceeded northern for the first time, but over inventory and pricing pressure led to layoffs, curtailment of hours, and withdrawal of capital by investors.

The Durham Hosiery Mill Co. felt the effects of the downturn by 1922, and “could not forestall indefinitely the closing of some of its mills.” In 1923, Julian Carr, Sr. auctioned off his farm in order to provide capital “because the Durham Hosiery Mill had to be saved.”

Mill Number 1 continued to produce cotton yarn and cotton menus socks until it was closed in 1934. Of the Durham plants, only the Silk Hosiery Mill remained in operation by the Durham Hosiery Mill Co. after this period.

Add new comment

Log in or register to post comments.